Understanding the Process of EV Charger Installation

Why EV Chargers Matter and How This Guide Is Structured

Electric vehicles are changing how we move, and chargers are the quiet infrastructure that makes that shift practical. A thoughtfully installed charger turns every night into a refueling session, reduces trips to public stations, and gives you predictable energy costs. On the public side, reliable charging unlocks longer road trips, supports fleet transitions, and helps businesses attract customers who stay longer while their vehicles top up. Whether you are a homeowner planning a tidy garage setup or a site operator coordinating transformers, parking layout, and software, understanding the process pays off in uptime, safety, and lower lifetime cost.

To keep this guide easy to use, here is the outline we will follow before diving deep into each part:

– Charger types and power levels: what they deliver, where they fit, and how to compare

– Residential installation: permits, panels, wiring, protection, placement, and commissioning

– Commercial and fleet infrastructure: site design, grid coordination, load management, and operations

– Costs, incentives, and maintenance: realistic budgets, savings pathways, and care routines

– A concluding roadmap: practical next steps for homeowners and site operators

Why it matters now: charging availability and performance directly shape EV satisfaction. Most daily driving needs can be met with overnight charging at home or at a workplace, which is why Level 2 installations are growing rapidly. Public locations add confidence for longer journeys and provide critical support to ride-hailing, delivery, and municipal fleets that run tight schedules. Meanwhile, utilities are updating tariffs and offering incentives that can significantly influence the economics of both home and commercial projects.

Throughout this article, you will find comparisons you can apply right away. We quantify how power levels translate into charging speed, explain load calculations without jargon, and point out code and safety considerations that are easy to miss on a first project. We also highlight common pitfalls—undersized conductors, poor cable management, and neglected commissioning—and offer ways to avoid them. By the end, you will have a clear path from idea to energized charger, plus a checklist you can hand to an electrician or project team.

Charger Types and Technical Basics: Power, Speed, and Practical Trade-offs

All EV charging delivers energy through either alternating current (AC) or direct current (DC), but how that energy gets to the battery determines speed, cost, and complexity. At the simplest end, household AC circuits can support low-power charging that adds modest range overnight. Step up to dedicated AC circuits and you reach medium power suitable for most daily driving. At the top end, DC equipment converts grid power for rapid charging directly into the battery, ideal for highway corridors and quick-turn fleets but requiring heavier infrastructure. The trade-offs revolve around power (kilowatts), circuit capacity (amperes), and duty cycle (how long equipment runs near its limit).

Typical reference points help with planning. Entry-level AC charging on a standard household outlet often provides roughly 1.2–1.8 kW, adding a handful of miles of range per hour—fine for low-mileage drivers or as a backup. Dedicated AC equipment commonly runs from about 7 to 11 kW on single-phase supply, with higher outputs possible on suitable circuits; this tends to add a few dozen miles of range per hour, enough for daily commuting after a short evening plug-in. DC equipment spans from around 50 kW for modest public sites up to 250–350 kW at high-throughput locations, where a 15–25 minute stop can meaningfully recharge modern packs. Remember, actual speed depends on the vehicle’s acceptance rate and battery temperature; power tapers as the battery fills, so stated kilowatts are a ceiling rather than a constant.

Beyond power, there are practical features that influence experience and longevity:

– Smart energy management allows multiple chargers to share a limited supply by allocating current dynamically

– Scheduled charging aligns sessions with lower tariffs, shaving costs without changing habits

– Weather protection matters: look for enclosures tested for dust and water ingress, with cable insulation rated for temperature swings

– Thermal management and efficiency: cooler-running equipment wastes less energy and maintains output in hot conditions, reducing nuisance derating

Connector styles vary by region and by AC versus DC, but most new vehicles and public sites align with the prevalent local standards. The key is compatibility: match your vehicle’s inlet with the charger’s output and confirm the cord length can reach comfortably without strain or trip hazards. For commercial sites, plan for a mixed vehicle population by including multiple parking positions and conduit stubs for future standards. In every case, balance today’s needs with tomorrow’s capacity; oversizing conduit and service pathways is often inexpensive insurance compared with tearing up pavement later.

Residential Installation: From Assessment to Energized Outlet

Successful home installations start with a clear picture of your electrical capacity and driving needs. Begin by reviewing your service panel rating and the diversity of existing loads—HVAC, cooking, laundry, and other high-draw appliances. A load calculation estimates whether your panel can accept a new dedicated circuit without tripping main breakers during peak usage. Many homes can support a 30–50 amp circuit for a Level 2 charger, but older panels may require an upgrade or a load management device that curtails charging when household consumption spikes. This is not guesswork; a licensed electrician can complete a formal calculation and propose options that keep you within code.

Next is permitting and code compliance. Most jurisdictions require an electrical permit for a new circuit and specify protective devices such as ground-fault and arc-fault protection depending on location. Garages and outdoor installations introduce additional rules: enclosures should be weather-rated, mounting heights must prevent cable drag and splash intrusion, and receptacles or hardwired units need proper strain relief. If the charger is outdoors, plan for sun exposure, snow clearance, and a cable reach that avoids stretching across walkways. Attention here prevents both nuisance tripping and premature wear.

The physical installation follows a logical sequence:

– Choose a mounting location near the parking position, minimizing cable run and avoiding sharp bends

– Pull appropriately sized conductors in conduit; copper is common, but aluminum may be viable on longer runs with correct sizing

– Install a dedicated breaker sized to the continuous load (typically 125% of the charger’s rated current)

– Add protective devices as required, then mount the unit and test for proper polarity, grounding, and insulation resistance

– Commission the charger: update firmware, set current limits, join Wi‑Fi if available, and verify scheduled charging

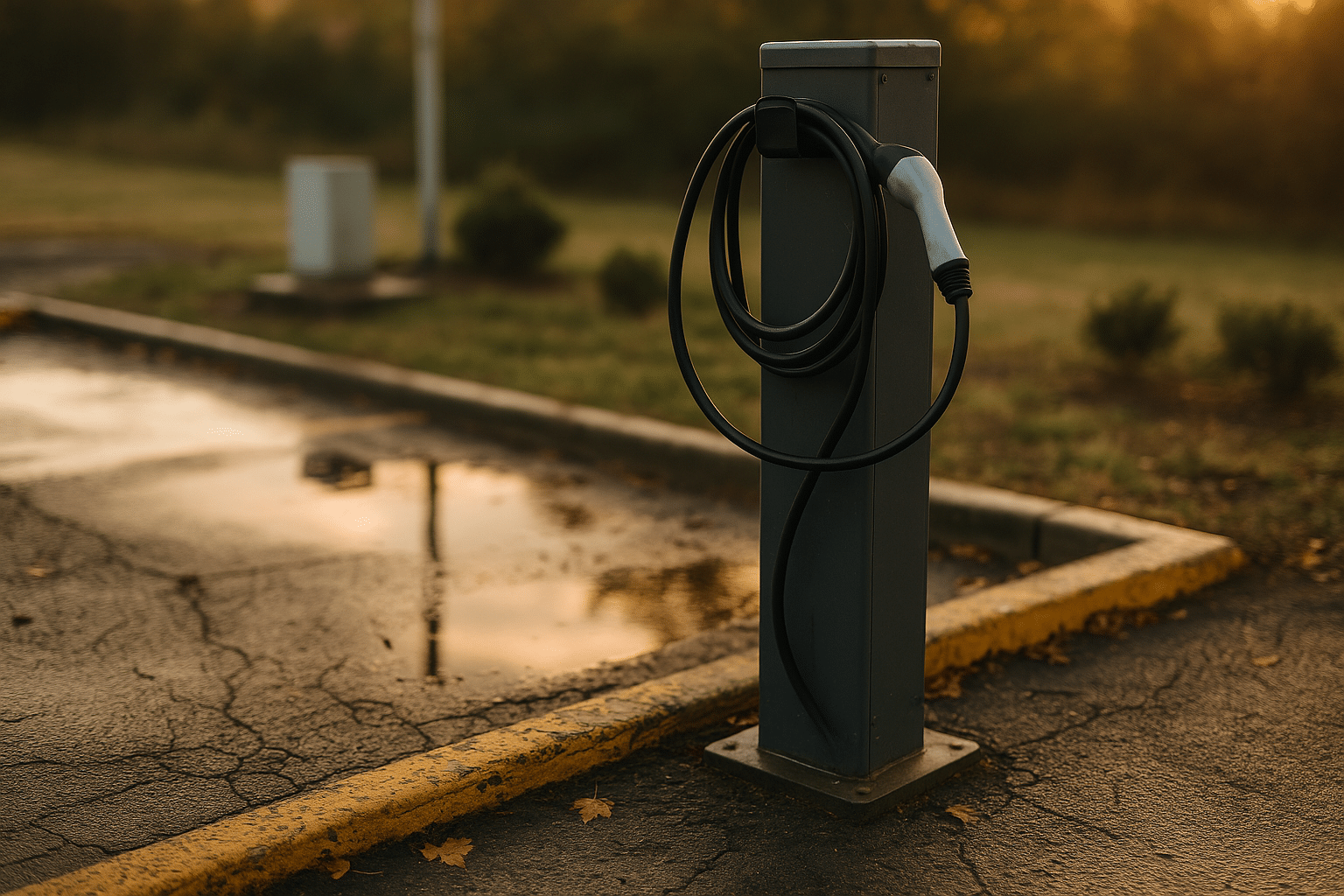

Practical details add quality. A tidy cable hook keeps the cord off the floor and away from tires, reducing abrasion. Conduit layout that follows straight lines and uses gentle sweeps looks professional and is easier to service. If trenching to a detached garage, respect burial depths and use marking tape to warn future diggers. Costs vary with distance and panel condition, but many homeowners see a combined equipment and labor range in the low thousands for a clean, code-compliant Level 2 setup. The payoff is daily convenience, predictable energy rates, and a quieter routine—plug in, walk away, and wake up to the range you need.

Commercial and Fleet Infrastructure: Designing for Reliability, Throughput, and Growth

Public and fleet charging introduces layers that go beyond a single circuit. Start with site selection: drivers value locations that feel safe, are well lit at night, and offer services while they wait. For fleets, yard logistics and driver workflow dominate—chargers must align with parking patterns, turning radii, and shift changes. From an electrical perspective, the main constraint is available capacity at the service entrance or nearby distribution. If the site’s load already pushes limits, you may need a service upgrade or to phase deployments as capacity becomes available. Treat civil work—concrete pads, bollards, drainage, and conduit paths—as assets that should outlast the first generation of hardware.

Reliability begins on paper. Redundant conduits, spare breaker spaces, and isolation switches allow maintenance without taking the entire site offline. Cable management prevents trip hazards and protects connectors from being dragged across pavement. Accessibility should be designed in from the start: clear access aisles, appropriate slopes, reachable controls, and unobstructed cable reach. Consider an equipment layout that separates parking from pedestrian paths to reduce conflict points, and position chargers where plow operations and curb debris will not bury cables in winter.

Operating cost is as important as construction cost. Demand charges on commercial tariffs can dominate the monthly bill if multiple high-power sessions overlap. Smart load management addresses this by distributing current among simultaneously charging vehicles to cap peaks. Time-of-use scheduling and reservation windows help smooth demand further. For sites with mixed dwell times—short stops and longer stays—consider a blend of medium-power AC for all-day parking and several DC positions for quick turns; this often raises total kilowatt-hours delivered per day without pushing the service to its limit.

Networking adds visibility and control. Open, standards-based communication lets you monitor uptime, set pricing, and apply remote diagnostics. Typical key metrics include session success rate, average energy per session, connector utilization, and mean time to repair. Design for a target uptime that drivers can rely on—above ninety-seven percent is a common internal benchmark—and back it with a service plan that includes rapid on-site response, spare parts, and clear escalation paths. As utilization grows, expansion is easier if you pre-installed extra conduit and left space on the pad; future-proofing saves not just money, but also the goodwill of drivers who expect consistent availability.

Costs, Incentives, Maintenance, and Conclusion: Your Next Steps

Budgeting for EV charging is more than the price of the box on the wall. On the residential side, costs typically include the charger, a dedicated circuit with breaker and conduit, potential panel work, and permit fees. A straightforward indoor install near the panel can be relatively affordable, while long outdoor runs, trenching, or service upgrades add substantial labor. Commercial projects add civil work, protective bollards, signage planning, network setup, and ongoing service contracts. For high-power DC, transformer coordination and utility studies become major line items. Lifecycle thinking ties it together: operational costs (energy plus demand charges), periodic maintenance, and occasional component replacements shape the true cost of ownership.

Financial help often exists if you look for it. Many national, regional, and utility programs offer rebates, tax credits, or make‑ready support that offsets equipment and infrastructure. Workplace and multi-unit residential buildings may qualify for additional incentives tied to accessibility or shared-use requirements. The application timelines can be strict, and funds may be released in phases, so align your project schedule with program windows. Keep documentation tidy—load calcs, invoices, photos, and inspection sign-offs—so you can submit cleanly and avoid delays. When incentives apply to networked equipment, confirm that your chosen model meets the required functionality before ordering.

Once energized, a light but consistent maintenance routine protects uptime:

– Quarterly inspection: check connectors, cables, strain reliefs, and enclosure seals for wear or damage

– Software updates: apply firmware and security patches promptly, then verify functionality with a short test session

– Cleaning: remove grit and debris from cable rests and pedestals; keep ventilation paths clear

– Recordkeeping: log issues, parts replaced, and response times to spot trends before they become outages

Conclusion: Whether you are outfitting a single-bay garage or a multi-stall public site, the path to reliable charging is straightforward when you plan deliberately. Choose power levels that match dwell times, size circuits with code and future growth in mind, and use smart controls to keep energy costs stable. Take advantage of incentives to stretch your budget, and commit to simple maintenance that preserves uptime. With a clear scope, a competent installer, and a willingness to think a step ahead, you set up drivers—yourself included—for convenient, confident charging every day.